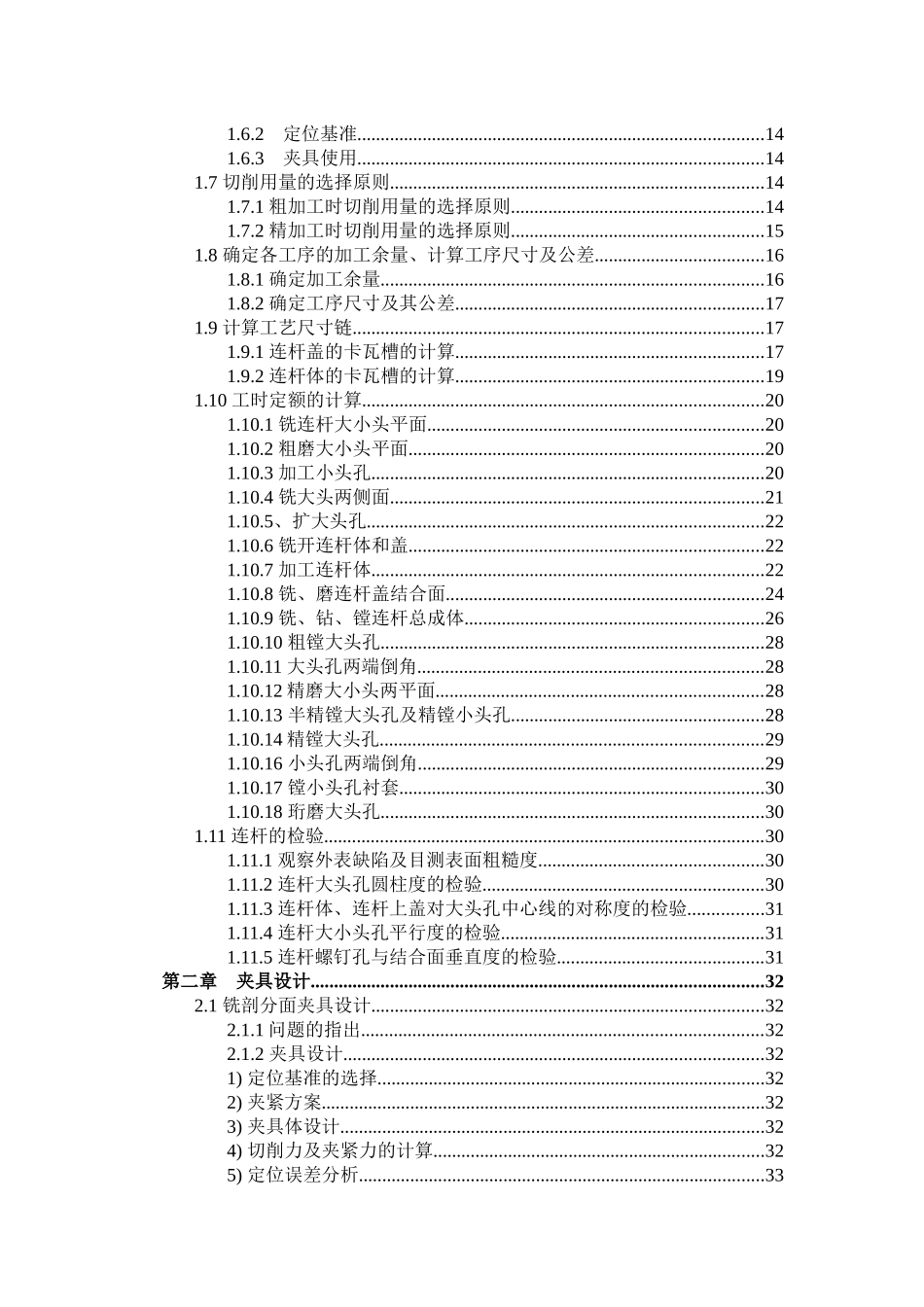

扬州职业大学设计题目:连杆件的加工及工装设计系别:机械工程系专业:机械制造及自动化班级:07机械(1)班姓名:丁聪聪学号:0701010107指导教师:傅锦完成时间:2010-4-23目录摘要....................................................................................................................4第一章连杆加工工艺.........................................................................................51.1连杆的结构特点..........................................................................................51.2连杆的主要技术要求..................................................................................51.2.1大、小头孔的尺寸精度、形状精度................................................61.2.2大、小头孔轴心线在两个互相垂直方向的平行度........................61.2.3大、小头孔中心距............................................................................61.2.4连杆大头孔两端面对大头孔中心线的垂直度................................61.2.5大、小头孔两端面的技术要求........................................................61.2.6螺栓孔的技术要求............................................................................71.2.7有关结合面的技术要求....................................................................71.3连杆的材料和毛坯...................................................................................71.4连杆的机械加工工艺过程.......................................................................91.5连杆的机械加工工艺过程分析................................................................111.5.1工艺过程的安排..............................................................................111.5.2定位基准的选择..............................................................................111.5.3确定合理的夹紧方法......................................................................121.5.4连杆两端面的加工..........................................................................131.5.5连杆大、小头孔的加工..................................................................131.5.6连杆螺栓孔的加工..........................................................................131.5.7连杆体与连杆盖的铣开工序..........................................................131.5.8大头侧面的加工..............................................................................141.6连杆加工工艺设计应考虑的问题............................................................141.6.1工序安排.......................................................................................141.6.2定位基准.......................................................................................141.6.3夹具使用.......................................................................................141.7切削用量的选择原则................................................................................141.7.1粗加工时切削用量的选择原则......................................................141.7.2精加工时切削用量的选择原则......................................................151.8确定各工序的加工余量、计算工序尺寸及公差....................................161.8.1确定加工余量..................................................................................161.8.2确定工序尺寸及其公差..................................................................171.9计算工艺尺寸链.....................................................................................

VIP

VIP VIP

VIP VIP

VIP VIP

VIP VIP

VIP VIP

VIP VIP

VIP VIP

VIP VIP

VIP VIP

VIP