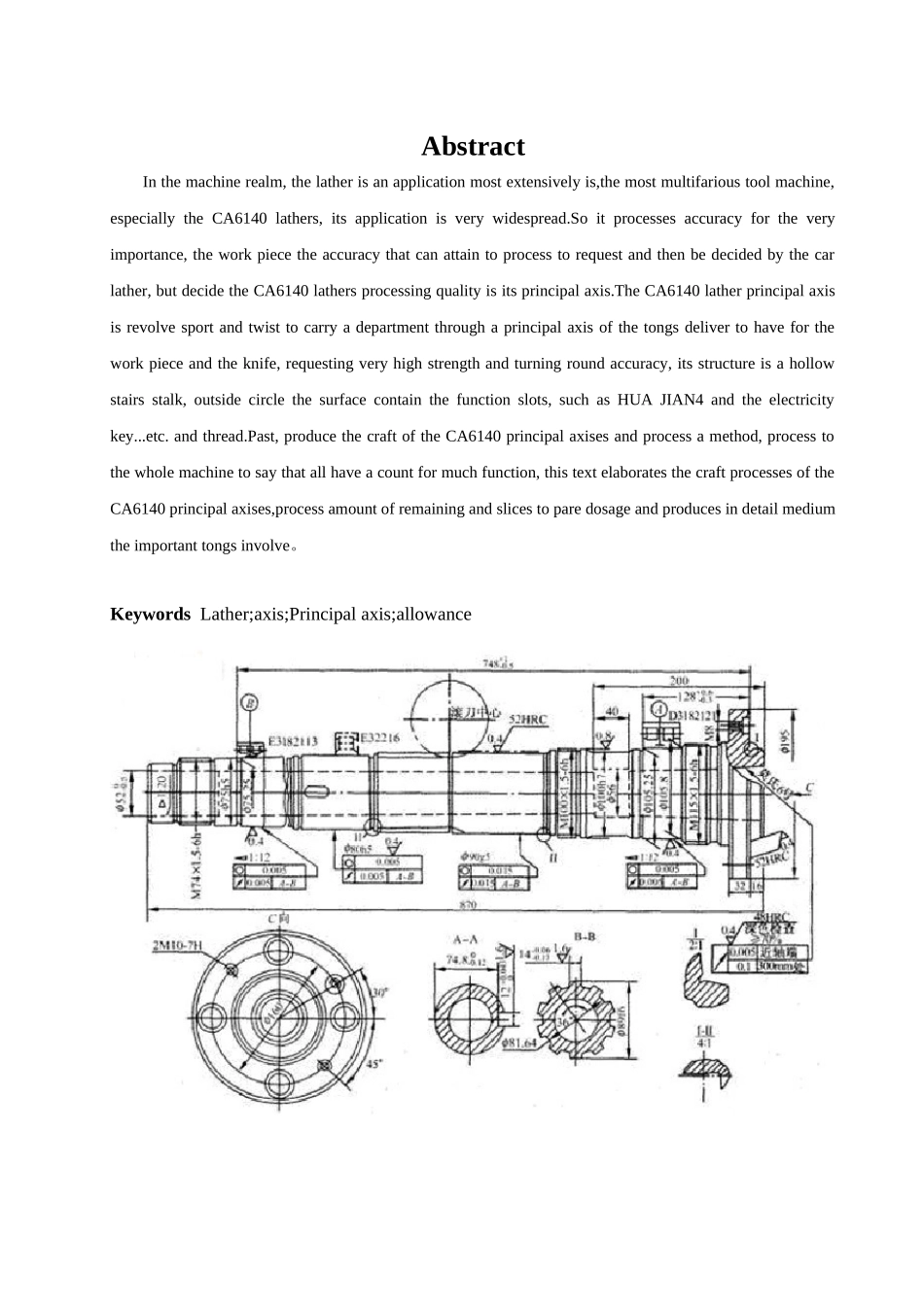

题目:车床主轴加工工艺过程姓名:班级学号:指导教师:摘要在机械领域中,车床是应用最广泛为、最为频繁的一种机床,它的应用非常的普遍。所以它的加工精度就极其的重要,工件能否达到加工要求就取决于车车床本身的精度,而决定车床加工质量的就是它的主轴。CA6140车床主轴是把旋转运动及扭矩通过主轴端部的夹具传递给工件和刀具,要求有很高的强度及回转精度,其结构为空心阶梯轴,外圆表面有花键、电键等功能槽及螺纹。故,生产CA6140主轴的工艺以及加工方法,对整个机械加工来说都有着非常重要的作用,本文详细阐述了CA6140主轴的工艺过程、加工余量、切削用量以及生产中所涉及的重要夹具关键词车床;主轴;旋转运动;公差AbstractInthemachinerealm,thelatherisanapplicationmostextensivelyis,themostmultifarioustoolmachine,especiallytheCA6140lathers,itsapplicationisverywidespread.Soitprocessesaccuracyfortheveryimportance,theworkpiecetheaccuracythatcanattaintoprocesstorequestandthenbedecidedbythecarlather,butdecidetheCA6140lathersprocessingqualityisitsprincipalaxis.TheCA6140latherprincipalaxisisrevolvesportandtwisttocarryadepartmentthroughaprincipalaxisofthetongsdelivertohavefortheworkpieceandtheknife,requestingveryhighstrengthandturningroundaccuracy,itsstructureisahollowstairsstalk,outsidecirclethesurfacecontainthefunctionslots,suchasHUAJIAN4andtheelectricitykey...etc.andthread.Past,producethecraftoftheCA6140principalaxisesandprocessamethod,processtothewholemachinetosaythatallhaveacountformuchfunction,thistextelaboratesthecraftprocessesoftheCA6140principalaxises,processamountofremainingandslicestoparedosageandproducesindetailmediumtheimportanttongsinvolve。KeywordsLather;axis;Principalaxis;allowance目录摘要IAbstractII第1章零件的分析...........................................................................................................21.1零件的作用....................................................................................................................21.1.1支承轴颈...................................................................................................................................21.1.2头部锥孔...................................................................................................................................21.1.3头部短锥...................................................................................................................................21.1.4装配轴颈...................................................................................................................................21.1.5轴向锁紧...................................................................................................................................31.2零件的工艺分析............................................................................................................31.2.1加工阶段的划分.......................................................................................................................31.2.2工序顺序安排...........................................................................................................................31.2.3主轴锥孔的磨削.......................................................................................................................4第2章工艺规程的设计...................................................................................................52.1主轴的材料、毛坯与热处理.......................................................................