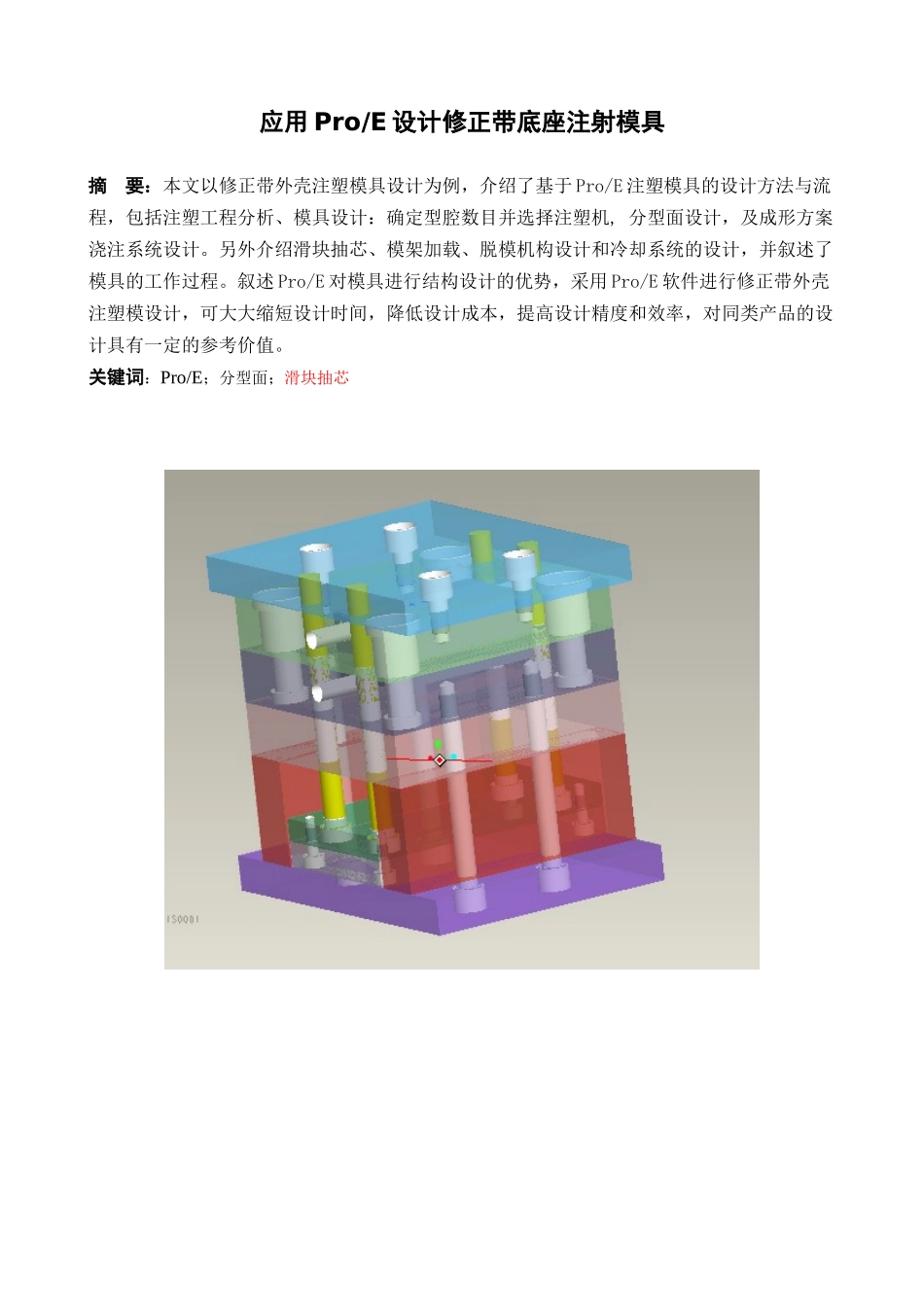

毕业设计(论文)正文题目应用PRO/E设计修正带底座注射模具专业机械设计制造及其自动化班级姓名指导教师职称2010年5月20日应用Pro/E设计修正带底座注射模具摘要:本文以修正带外壳注塑模具设计为例,介绍了基于Pro/E注塑模具的设计方法与流程,包括注塑工程分析、模具设计:确定型腔数目并选择注塑机,分型面设计,及成形方案浇注系统设计。另外介绍滑块抽芯、模架加载、脱模机构设计和冷却系统的设计,并叙述了模具的工作过程。叙述Pro/E对模具进行结构设计的优势,采用Pro/E软件进行修正带外壳注塑模设计,可大大缩短设计时间,降低设计成本,提高设计精度和效率,对同类产品的设计具有一定的参考价值。关键词:Pro/E;分型面;滑块抽芯DesignofinjectionmoldforcorrectiontapebackcoverbasedonPro/EAbstract:Takingthecorrectiontapebackcoverforexample,paperintroducedthemethodoftheinjectionmoulddesignbasedonPro/E,anditincludemoldedplasticengineeringanalysis,moulddesign:fixingthenumberofcavity,selectingtherightinjectionmachineandcreatingpartingsurfaces,maketheshapescheme,thisiscontainedtotalstructuredesign,byhotrunnersystem,improvethesurfacequalityandmoldingsefficiency,makefulluseofresourcesaveenergy.Besides,sliderlifter,dividingadesignforface,sprinklingtonotethesystemdesign,state-listed,takeoffdesignandcoolsystemdesign,Further,moldworkingprocessintroduce.Theprocessofauto-optimizationdesignofmouldstructure,theprocessofdesignbasedonPro/Esoftwarecangreatlyshortenthetimeandlowerthecost,improvetheprecisionandefficiency.Itcanbecertainreferencetothedesignofsimilarproducts.Keywords:Pro/E;Partingsurface;Sliderlifter目录第1章概述........................................................................................................11.1设计项目概述..........................................................11.2模具工业的重要性......................................................11.3我国模具技术的现状及前景..............................................3第2章塑件成型工艺分析......................................................................................42.1塑件三维造型过程.......................................................42.2塑件的拔模斜度.........................................................62.3修正带外壳分析........................................................82.3.1塑料制品的设计原则................................................82.3.2设计塑料制品的注意事项...........................................82.3.3ABS的性能及其注射工艺分析........................................92.3.4注射成型过程......................................................92.3.5注射工艺参数......................................................92.3.6ABS成型塑件的主要缺陷及消除措施.................................10第3章浇注系统及冷却系统设计...........................................................................113.1浇注系统.............................................................113.1.1流道的设计......................................................113.1.2浇口的设计.....................................................123.2冷却系统的设计.......................................................123.3排气系统的设计.......................................................13第4章模具结构形式和注射机的确定.............................................144.1型腔及分型面数目的确定...............................................144.2注射机的选取和校核...................................................164.2.1选择注射机所需参数计算.................................