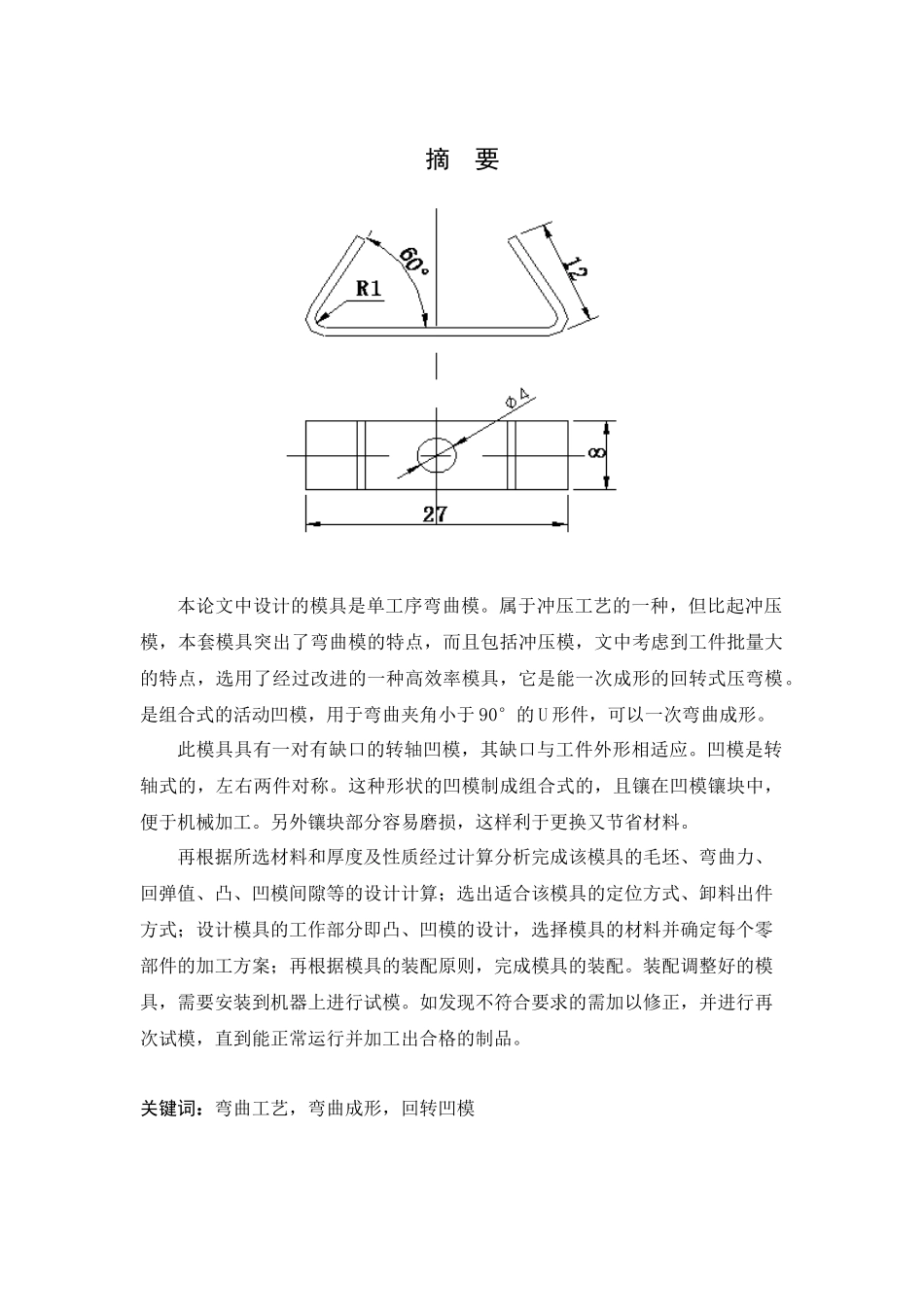

摘要本论文中设计的模具是单工序弯曲模。属于冲压工艺的一种,但比起冲压模,本套模具突出了弯曲模的特点,而且包括冲压模,文中考虑到工件批量大的特点,选用了经过改进的一种高效率模具,它是能一次成形的回转式压弯模。是组合式的活动凹模,用于弯曲夹角小于90°的U形件,可以一次弯曲成形。此模具具有一对有缺口的转轴凹模,其缺口与工件外形相适应。凹模是转轴式的,左右两件对称。这种形状的凹模制成组合式的,且镶在凹模镶块中,便于机械加工。另外镶块部分容易磨损,这样利于更换又节省材料。再根据所选材料和厚度及性质经过计算分析完成该模具的毛坯、弯曲力、回弹值、凸、凹模间隙等的设计计算;选出适合该模具的定位方式、卸料出件方式;设计模具的工作部分即凸、凹模的设计,选择模具的材料并确定每个零部件的加工方案;再根据模具的装配原则,完成模具的装配。装配调整好的模具,需要安装到机器上进行试模。如发现不符合要求的需加以修正,并进行再次试模,直到能正常运行并加工出合格的制品。关键词:弯曲工艺,弯曲成形,回转凹模AbstractThedesignofthemoldinthispaperisthebendingmodulusofasingleprocess.Belongtoastampingprocess,butcomparedtothestampingdiesetsofmoldshighlightsthecharacteristicsofthebendingdieandstampingmold,inthispaper,weconsidertheworkpiecevolume,thechoiceofahigh-efficiencyimprovedmold,itiscanformingarotarybendingmode.ThecombinedactivitiesofthediefortheU-shapedbendanglelessthan90°,timebendingandforming.Thismoldhasapairofshaftthediegaptoadaptitsgapwiththeworkpieceshape.Thedieistheshaft,abouttwosymmetric.Theshapeoftheconcavemoldmademodular,andinsertinthedieinsert,easeofmachining.Inaddition,theinsertpartiseasytowear,soconducivetochangeandsavematerial.Thedeclineofthepunchwiththepresstheslider,thefirstblankwithinthediebentintoaU-shapedpieceof90°,pressuretoturnthediewhenthepunchcontinuedtodecline,thebottomoftheblank,rotatingthedieforcerotationtheblanksandfurtherbendingandforming.Driverotatingthediewhenthereboundofthepunchwiththepresstheslider,thereverserotationlimitnailandtheaxisofthespringsothattherotationofthediereset.Bendingthedieduetothisstructurecanbecompletedinthepressatourofseveralpairsofsimplemoldtocompletethebendingprocess,themoldstructureisnotcomplicated,somoreinproduction.Thencalculatedaccordingtotheselectedmaterialandthethicknessandnatureoftheanalysisoftherough,bendingforce,springbackvalue,convex,concavemoldgapofthemold;electedforthepositioningofthemold,andunloadingthepiecesoftheway;molddesignpartoftheconvexdesignofthedie,thechoiceofmoldmaterialandtodeterminetheprocessingofeachcomponentprogram;completethemoldassemblyaccordingtothemoldassemblyprinciples.Assemblyadjustedthemoldtryoutneedstobeinstalledonthemachine.Foundtonotmeettherequirementsneedtobeamendedandre-testmode,untilthenormaloperationandprocessingofqualifiedproducts.Keywords:Bending,bending,rotatingthedie1弯曲工艺性分析1.1分析零件的冲压工艺性并确定工艺方案名称:夹形零件回转轴弯曲模材料:T10A厚度:零件简图:如图1.1所示图1.1夹形零件1.2弯曲件的工艺性弯曲件的工艺性是指弯曲件的形状、尺寸、精度、材料及技术要求等是否符合弯曲加工的工艺要求。具有良好工艺性的弯曲件,不仅能减少废品率,而且能简化弯曲的工艺过程和模具结构,提高工件的质量。1.2.1弯曲件的精度弯曲件的精度受坯料定位、偏移、翘曲和回弹等因素的影响,弯曲的工序数目越多,精度也越低。一般弯曲件的经济公差等级在IT13级以下,角度公差大于15′。1.2.2弯曲件的材料如果弯曲件的材料具有足够的塑性,屈强比小,屈服点与弹性模量的比值小,则有利于弯曲成形和工件质量的提高。如软刚、黄铜和铝等材料的弯曲成形性能好。而脆性较大的材料,...