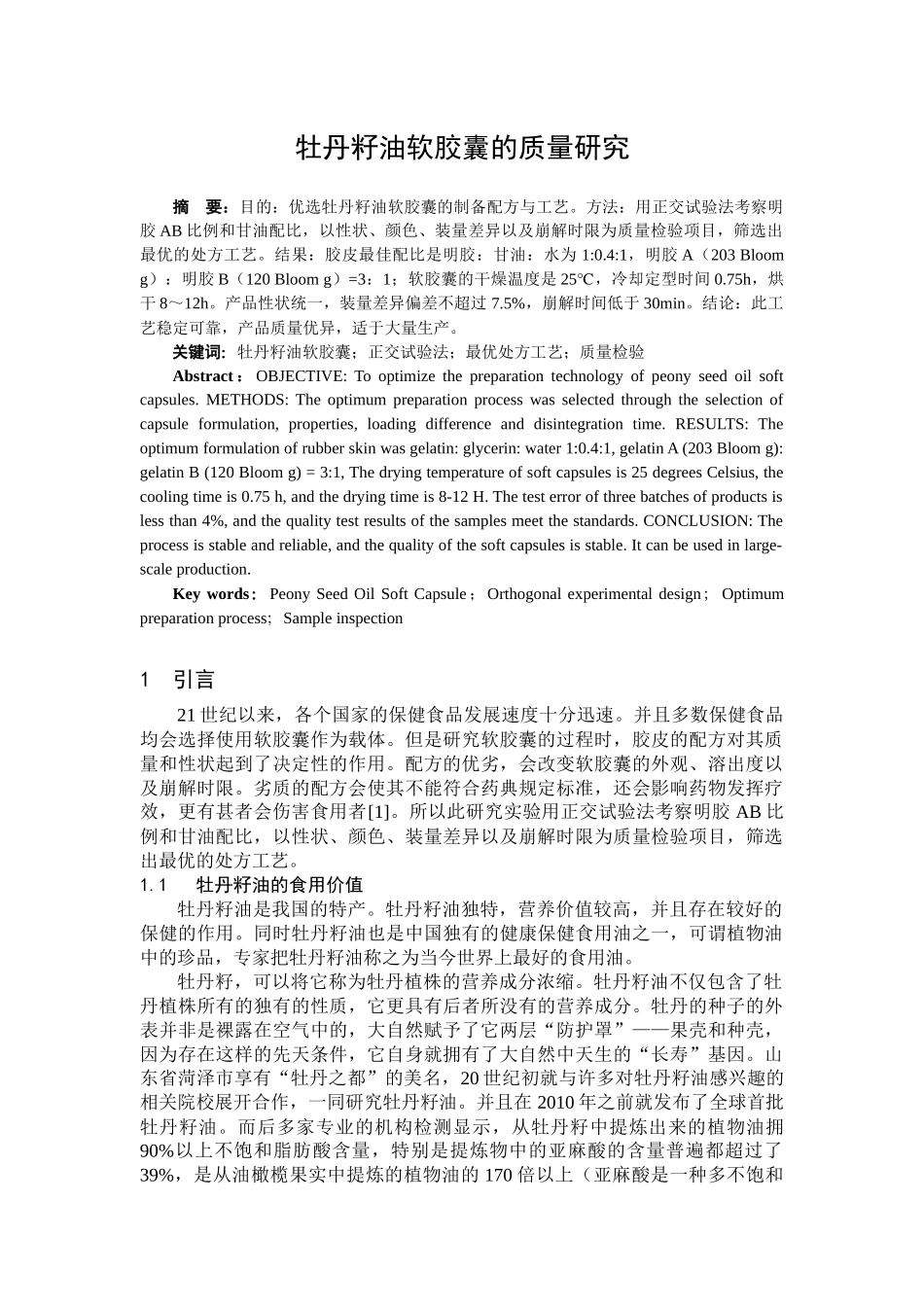

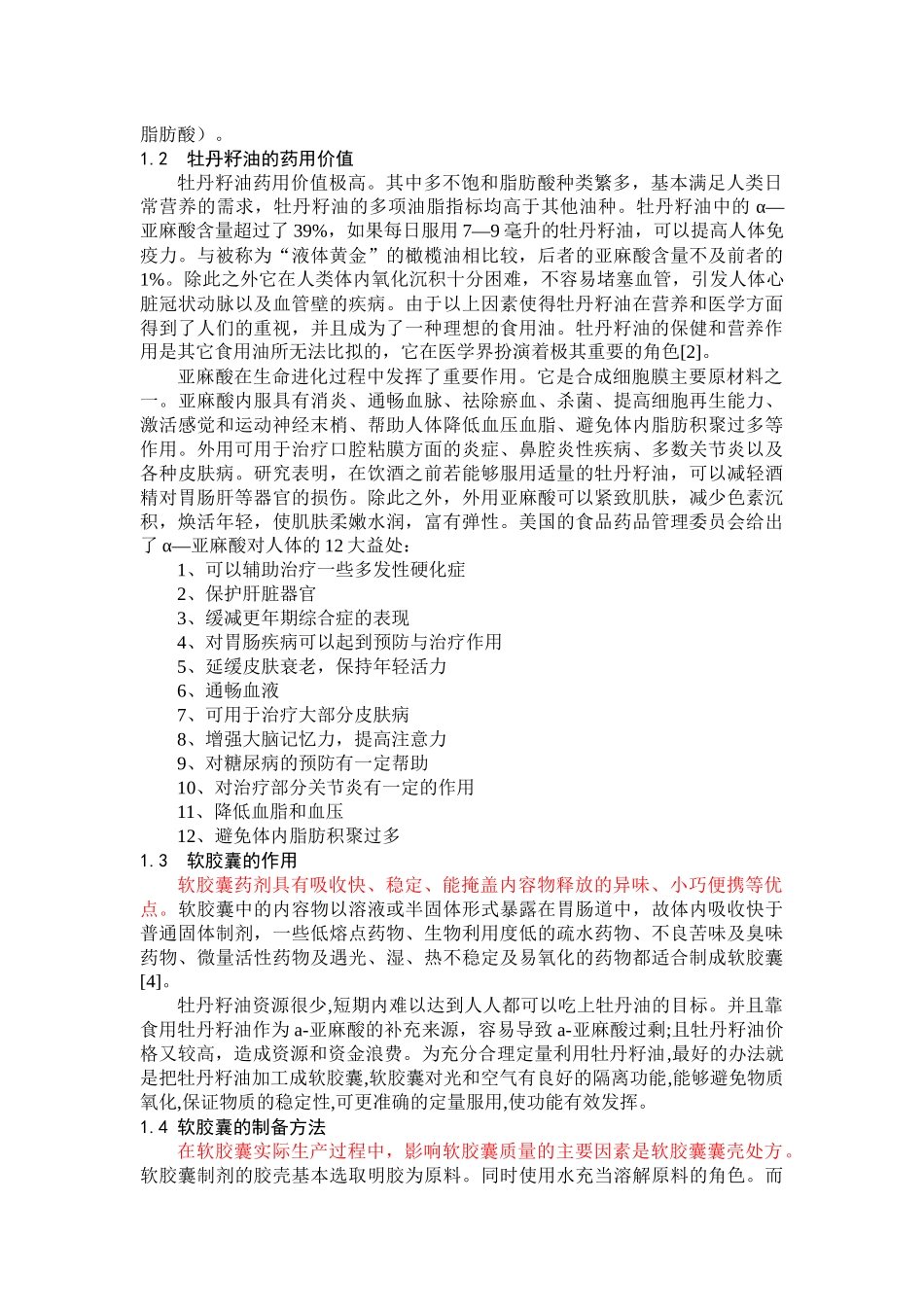

牡丹籽油软胶囊的质量研究摘 要:目的:优选牡丹籽油软胶囊的制备配方与工艺。方法:用正交试验法考察明胶 AB 比例和甘油配比,以性状、颜色、装量差异以及崩解时限为质量检验项目,筛选出最优的处方工艺。结果:胶皮最佳配比是明胶:甘油:水为 1:0.4:1,明胶 A(203 Bloom g):明胶 B(120 Bloom g)=3:1;软胶囊的干燥温度是 25℃,冷却定型时间 0.75h,烘干 8~12h。产品性状统一,装量差异偏差不超过 7.5%,崩解时间低于 30min。结论:此工艺稳定可靠,产品质量优异,适于大量生产。关键词:牡丹籽油软胶囊;正交试验法;最优处方工艺;质量检验Abstract : OBJECTIVE: To optimize the preparation technology of peony seed oil soft capsules. METHODS: The optimum preparation process was selected through the selection of capsule formulation, properties, loading difference and disintegration time. RESULTS: The optimum formulation of rubber skin was gelatin: glycerin: water 1:0.4:1, gelatin A (203 Bloom g): gelatin B (120 Bloom g) = 3:1, The drying temperature of soft capsules is 25 degrees Celsius, the cooling time is 0.75 h, and the drying time is 8-12 H. The test error of three batches of products is less than 4%, and the quality test results of the samples meet the standards. CONCLUSION: The process is stable and reliable, and the quality of the soft capsules is stable. It can be used in large-scale production.Key words:Peony Seed Oil Soft Capsule;Orthogonal experimental design;Optimum preparation process;Sample inspection1 引言 21 世纪以来,各个国家的保健食品发展速度十分迅速。并且多数保健食品均会选择使用软胶囊作为载体。但是研究软胶囊的过程时,胶皮的配方对其质量和性状起到了决定性的作用。配方的优劣,会改变软胶囊的外观、溶出度以及崩解时限。劣质的配方会使其不能符合药典规定标准,还会影响药物发挥疗效,更有甚者会伤害食用者[1]。所以此研究实验用正交试验法考察明胶 AB 比例和甘油配比,以性状、颜色、装量差异以及崩解时限为质量检验项目,筛选出最优的处方工艺。1.1...