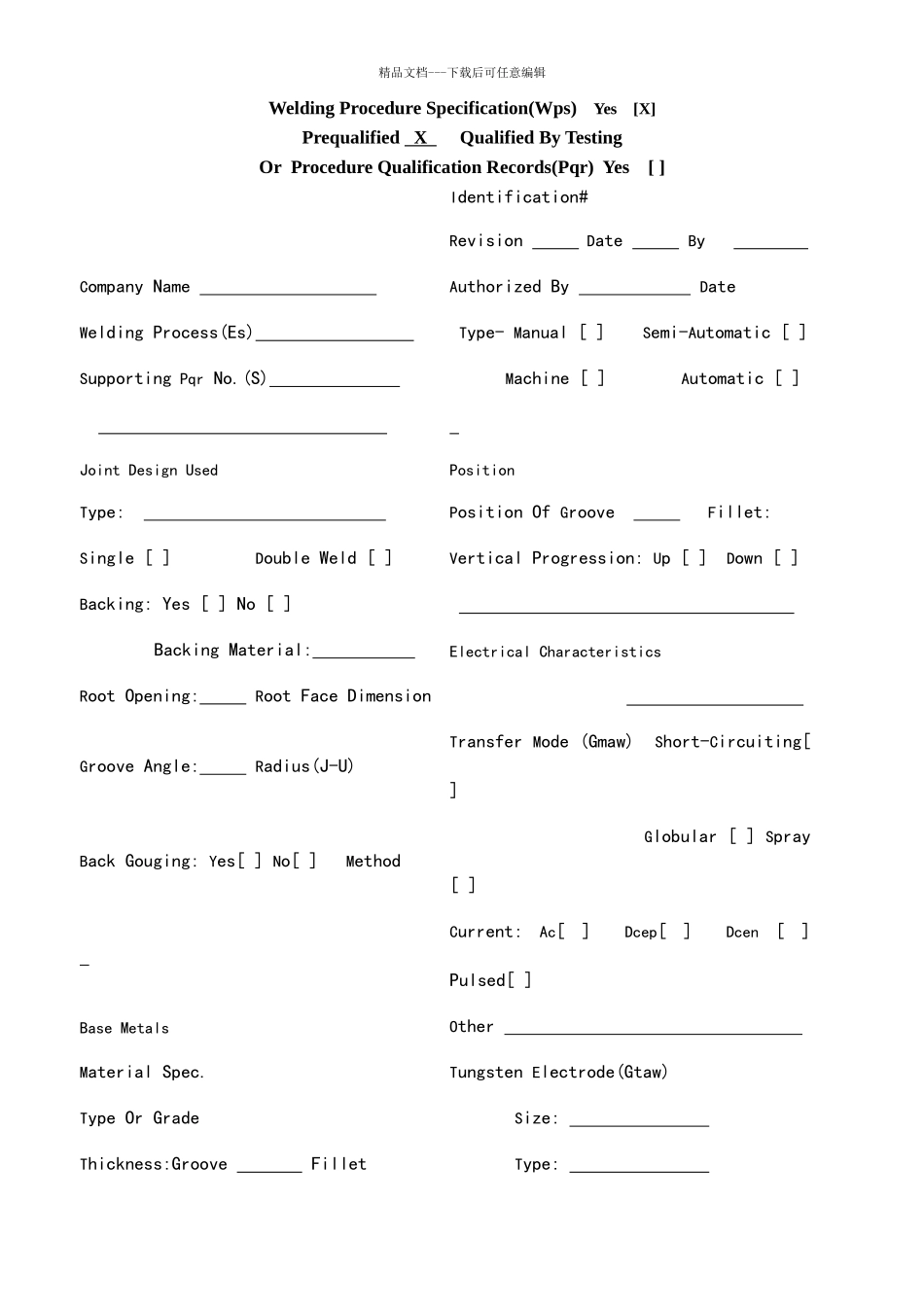

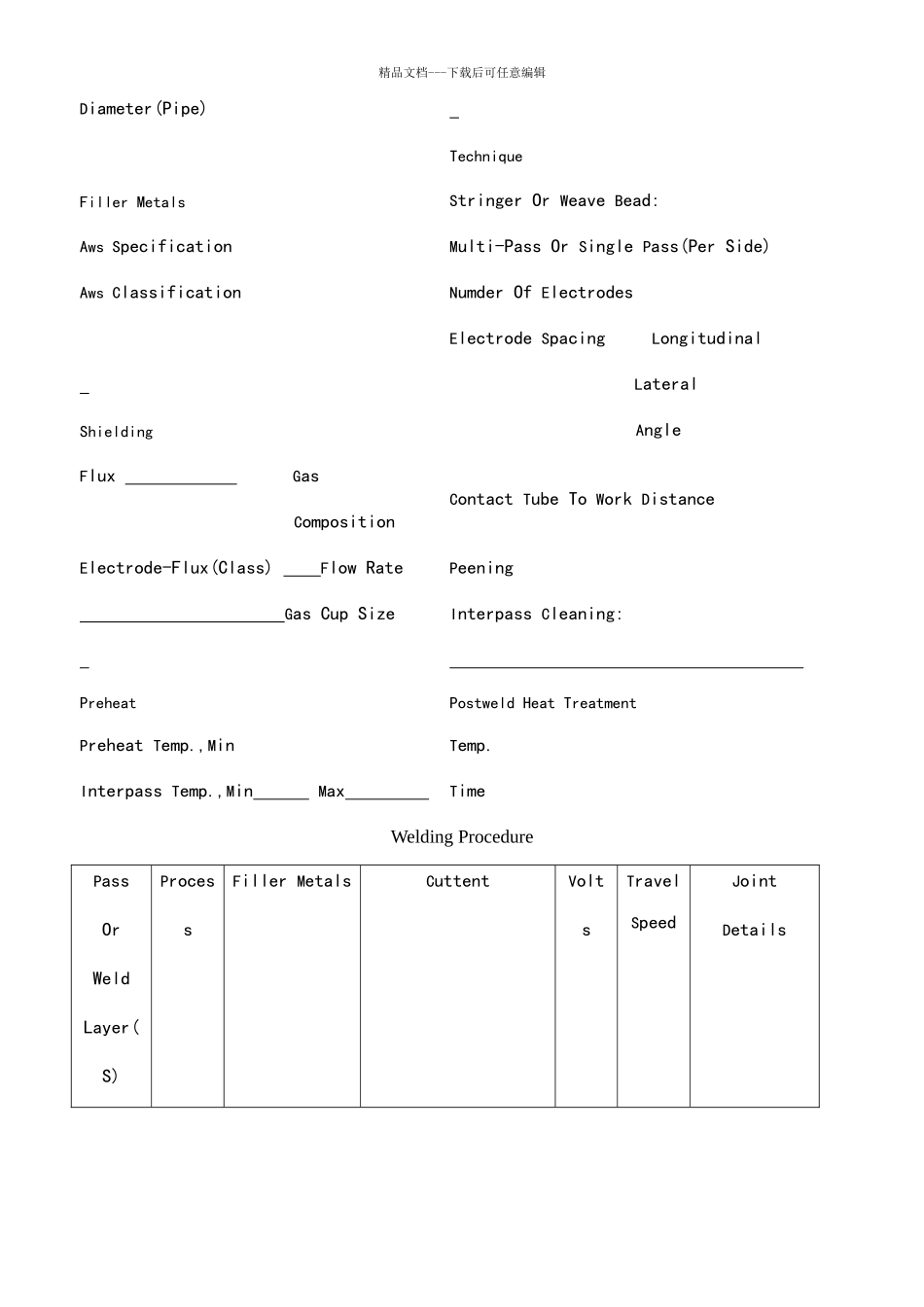

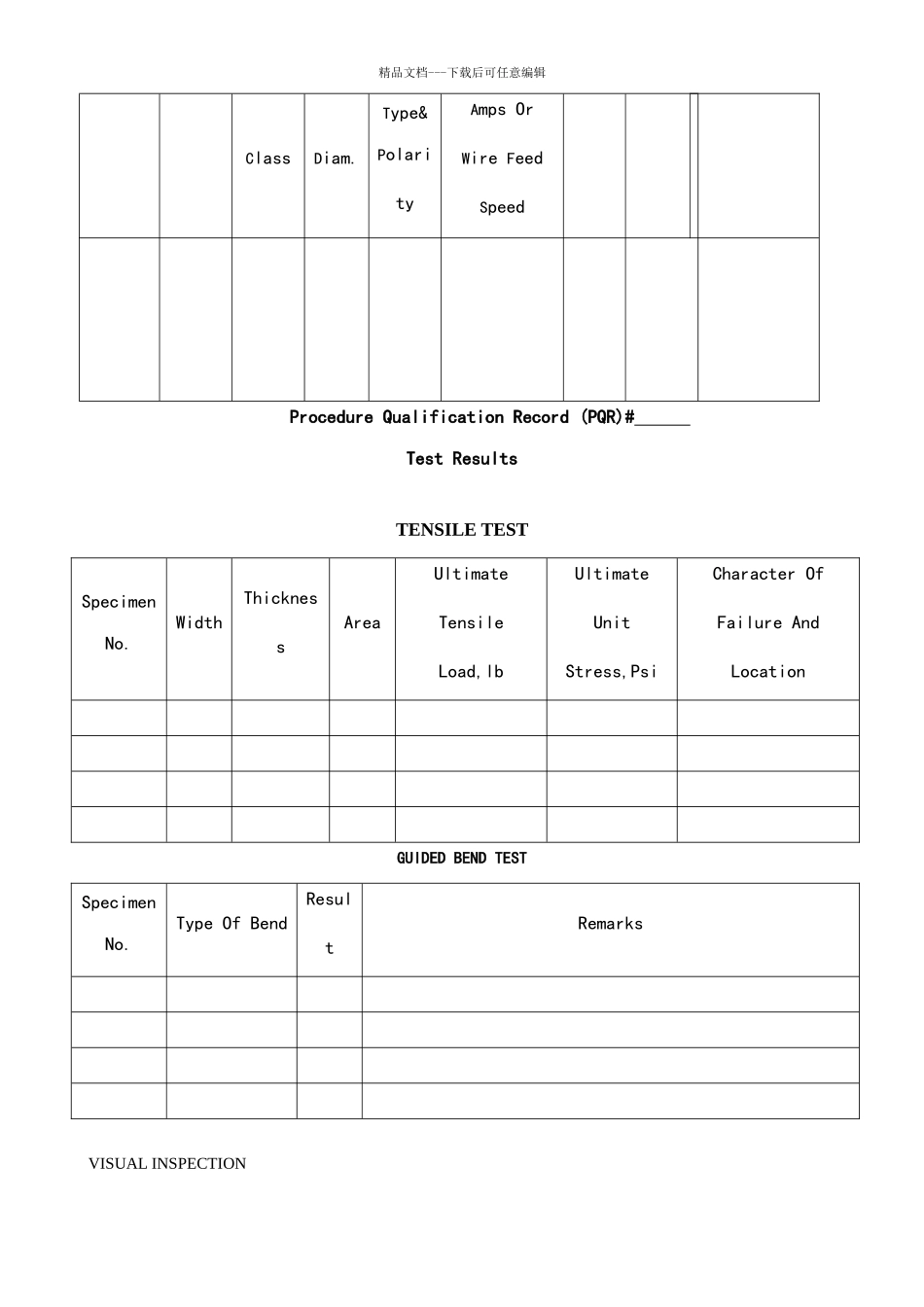

精品文档---下载后可任意编辑Welding Procedure Specification(Wps) Yes [X]Prequalified X Qualified By TestingOr Procedure Qualification Records(Pqr) Yes [ ]Identification# Revision Date By Company Name Authorized By Date Welding Process(Es) Type- Manual [ ] Semi-Automatic [ ] Supporting Pqr No.(S) Machine [ ] Automatic [ ] Joint Design UsedPositionType: Position Of Groove Fillet: Single [ ] Double Weld [ ]Vertical Progression: Up [ ] Down [ ]Backing: Yes [ ] No [ ] Backing Material: Electrical CharacteristicsRoot Opening: Root Face Dimension Groove Angle: Radius(J-U) Transfer Mode (Gmaw) Short-Circuiting[ ]Back Gouging: Yes[ ] No[ ] Method Globular [ ] Spray [ ] Current: Ac[ ] Dcep[ ] Dcen [ ] Pulsed[ ]Base MetalsOther Material Spec. Tungsten Electrode(Gtaw)Type Or Grade Size: Thickness:Groove Fillet Type: 精品文档---下载后可任意编辑Diameter(Pipe) TechniqueFiller MetalsStringer Or Weave Bead: Aws Specification Multi-Pass Or Single Pass(Per Side) Aws Classification Numder Of Electrodes Electrode Spacing Longitudinal Lateral Shielding Angle Flux Gas Contact Tube To Work Distance Composition Electrode-Flux(Class) Flow Rate Peening Gas Cup Size Interpass Cleaning: PreheatPostweld Heat TreatmentPreheat Temp.,Min Temp. Interpass Temp.,Min Max Time Welding ProcedurePass Or Weld Layer(S)ProcessFiller MetalsCuttentVoltsTravelSpeedJoint Details精品文档---下载后可任意编辑ClassDiam.Type&PolarityAmps Or Wire Feed SpeedProcedure Qualification Record (PQR)# Test ResultsTENSILE TESTSpecimenNo.WidthThicknessAreaUltimate Tensile Load,lbUltimate Unit Stress,PsiCharacter Of Failure And LocationGUIDED BEND TESTSpecimenNo.Type Of BendResultRemarksVISUAL INSPECTION精品文档---下载后可任意编辑Appearance Radiographic-Ultrasonic ExaminationUndercut RT report no: Result Piping Porosity UT report no: Result Convexity (FILLET WELD TEST RESULTS)Test Date Minimum Size Multiple Pass Maximum Size Single PassWitnesses By Macroetch Macroetch1. 3. 1. 3. 2. 2. All-weld-metal tension testOther testsTensile strength ,psi Yield point/strength,psi Elongation in 2 in,% Laboratory test no.Welder’s name Clock no. stamp no. Test’s conducted by Laboratory Test number Per We,the undersigned,certify that the statements in this record are correct and that the test welds were prepared,welded,and tested in accordance with the requirements of section 4 of AMSI/AWS ,( 86 ) structural welding code-steel. YearSigned By Title 精品文档---下载后可任意编辑Date